CNC MACHINING TECHNOLOGY

SKM Industries Inc. is your source for quality CNC machining for metal parts, plastics, and high precision assemblies. With mechanical engineers on staff, we give you the benefit of over 30 years of industry experience and the latest in equipment and computer technology.

A Strong Industry Reputation

Since our establishment in 1992, SKM Industries has built a strong industry reputation for providing highly accurate, quality parts with a high level of customer service and attention.

I know we can always rely on SKM Industries for high quality work delivered on time. We really do appreciate all the hard work.

Steven Inlow

I just wanted to say thank you SKM Industries for a job well done on our order. My quality control team was very impressed with their work. We look forward to sending in more orders.

Kevin McDevitt

Working with SKM Industries has been a terrific experience. We were really impressed with the final result and are very thankful.

Michael Portnoy

GRAVITATIONAL WAVES

In 2015, SKM Industries Inc. was selected by Caltech to manufacture parts for LIGO and Advanced LIGO projects for the historic discovery of gravitational waves.

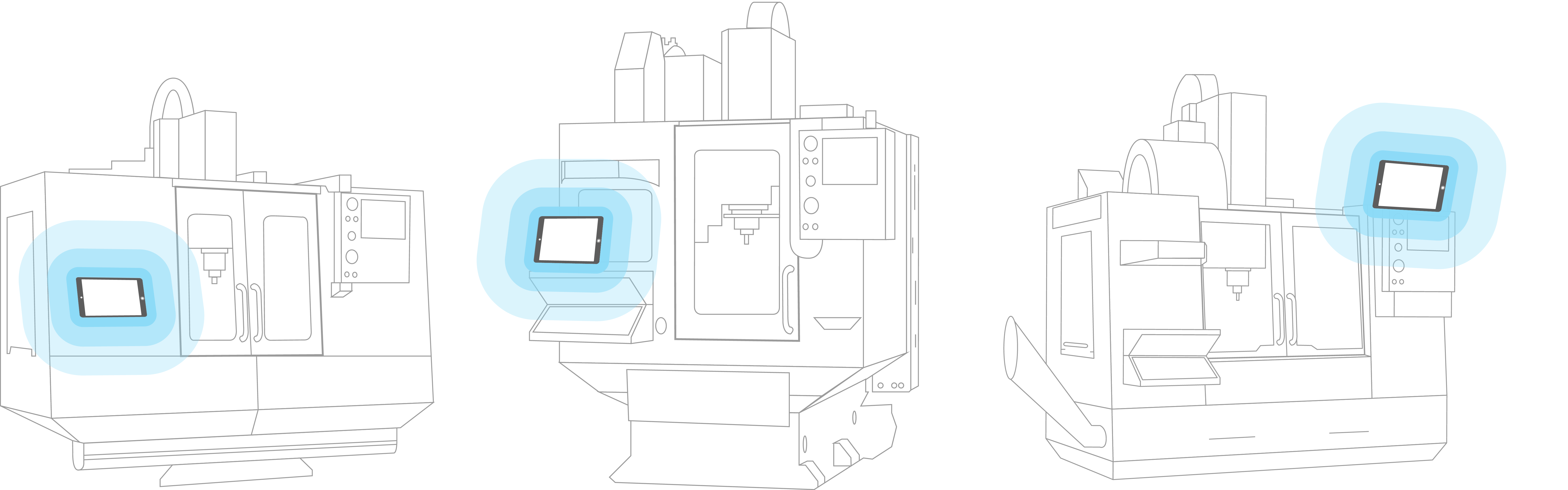

A PAPERLESS SHOP FLOOR

SKM Industries’ Custom Information System is designed to manage and integrate data for each customer work order. We run a unique complete information management system allowing for an entirely paperless shop floor.

INFORMATION MANAGEMENT

All customer data, such as quality assurance specifications, part materials, or processes is organized and stored into this system, easily accessible upon request or for repeat orders.

INFORMATION DEPLOYMENT

With iPads on all workstations tied into the central server, our system facilitates the information flow throughout the company with complete traceability and document control.

INDUSTRIES SERVED

SKM is committed to quality and excellence. We set the highest standards for ourselves, enabling us to meet and exceed our customers’ exacting specifications, regardless of whether that involves an independent consultant or a major corporation.

AEROSPACE

COMMERCIAL

ELECTRONICS

MACHINING

MEDICAL

MILITARY

SCIENTIFIC R&D

OUR GREEN INITIATIVE

SKM Industries is proud to announce its commitment to a greener future. Today, 70% of shop power consumption relies on 8,000 square feet of facility-mounted solar panels, and the custom ERP system allows for an entirely paperless shop floor.

CONTACT US TODAY

To request a quote, email us at sales@skmindustries.com. To simply learn more, fill out the form below or call us.

(661) 294-8373

28966 North Hancock Parkway

Valencia, CA 91355

28966 North Hancock Parkway

Valencia, CA 91355

Copyright © 2023 SKM Industries Inc.